The key design concept of the PSS is to remove/trap suspended particles/solids from the water which would typically flow straight through many vortex bays and thus pollute any biological media. This is especially the case in that small diameter vortex units are not the ultimate in efficiency. In brief then the PSS can be classified as a highly refined vortex unit, which of course means that any existing filter (or bays) require far less maintenance - also meaning a greater biological bed is established. Who could ever argue that this is not a great asset worth having ?

Trapping of particles/solids is achieved via Cloverleaf’s uniquely designed and manufactured long life Particle Separation Media (PSM) which is retained in suspension at all times. When the PSM (media) becomes blocked it is time for it to be cleaned via the airstone ring, however any blockage which is visually indicated by water flowing up through the central overflow does not substantially reduce the flow rate through the rest of any filter system (where applicable) - so general flow rates/performance are never greatly restricted. Biological integrity of the PSM (media) is always fully maintained in that it is always ONLY ever cleaned via oxygen rich mature pond water.

Although Cloverleaf spent many months experimenting with numerous existing floating media from international sources, various shortcomings led to the final decision for the company to invest in expensive tooling costs in order to manufacture the PSM media at its own new Essex based factory - with the media design being based on that used by a UK national water supply utility company.

To summarise, the PSS is British at its best and contributes to a better pond environment together with less pond maintenance at a price that can only be described as most reasonable. Unlike perhaps some manufacturers the Cloverleaf design concept is not solely based on having to rip out and cast aside any existing filtration system, when the option does exist to retain any existing pump fed system if desired.

Please note air pump’s are not supplied as part of the PSS, but Cloverleaf’s C82 Air Pump is great for the job.

Cleaning of the media is achieved via the following easy steps:

(1) Close isolation valve on PSS bay

(2) Switch off submersible pump

(3) Activate air ring/air pump for several minutes

(4) Turn off air pump

(5) Immediately open PSS bay waste valve to discharge foul water

(6) Wipe top perforated plate in bay with a few sheets of kitchen roll paper

(7) Re-activate system

Do not clean the PSS unnecessarily. Only do so when the overflow is seen to be operational. If PSS1 or PSS2 is connected into an existing multi bay filter system and the media to that system requires cleaning then also close the isolating valve on the PSS first in order to prevent foul water from running back to the pump.

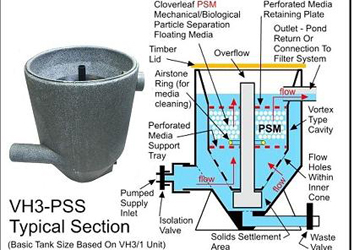

Explanation Of PSS: In brief Cloverleaf’s innovative but uncomplicated design for the PSS (Particle Separation System) can as a single bay/module be used in a stand alone situation (providing mechanical & biological filtration), and could also make a superb filter if attached to a skimmer. Alternatively the PSS (as a single module) can be hooked into any existing pump fed multi-bay filter system where it would replace any vortex bay - with any existing vortex then being converted into a bona-fide biological bay/chamber.

The key design concept of the PSS is to remove/trap suspended particles/solids from the water which would typically flow straight through many vortex bays and thus pollute any biological media. This is especially the case in that small diameter vortex units are not the ultimate in efficiency. In brief then the PSS can be classified as a highly refined vortex unit, which of course means that any existing filter (or bays) require far less maintenance - also meaning a greater biological bed is established. Who could ever argue that this is not a great asset worth having ?

Trapping of particles/solids is achieved via Cloverleaf’s uniquely designed and manufactured long life Particle Separation Media (PSM) which is retained in suspension at all times. When the PSM (media) becomes blocked it is time for it to be cleaned via the airstone ring, however any blockage which is visually indicated by water flowing up through the central overflow does not substantially reduce the flow rate through the rest of any filter system (where applicable) - so general flow rates/performance are never greatly restricted. Biological integrity of the PSM (media) is always fully maintained in that it is always ONLY ever cleaned via oxygen rich mature pond water.

Although Cloverleaf spent many months experimenting with numerous existing floating media from international sources, various shortcomings led to the final decision for the company to invest in expensive tooling costs in order to manufacture the PSM media at its own new Essex based factory - with the media design being based on that used by a UK national water supply utility company.

To summarise, the PSS is British at its best and contributes to a better pond environment together with less pond maintenance at a price that can only be described as most reasonable. Unlike perhaps some manufacturers the Cloverleaf design concept is not solely based on having to rip out and cast aside any existing filtration system, when the option does exist to retain any existing pump fed system if desired.

Please note air pump’s are not supplied as part of the PSS, but Cloverleaf’s C82 Air Pump is great for the job.

Cleaning of the media is achieved via the following easy steps:

(1) Close isolation valve on PSS bay

(2) Switch off submersible pump

(3) Activate air ring/air pump for several minutes

(4) Turn off air pump

(5) Immediately open PSS bay waste valve to discharge foul water

(6) Wipe top perforated plate in bay with a few sheets of kitchen roll paper

(7) Re-activate system

Do not clean the PSS unnecessarily. Only do so when the overflow is seen to be operational. If PSS1 or PSS2 is connected into an existing multi bay filter system and the media to that system requires cleaning then also close the isolating valve on the PSS first in order to prevent foul water from running back to the pump.